Over the past 15 years we’ve been supplying two different grades of fabric and depending on the application we’ve been recommending one or the other. The most common fabric has been a dyed polyester, and we’ve offered PVC as an optional upgrade. But recently we’ve decided that it’s time to innovate in our market and take the next leap forward - so we’ve developed NextUV which is now setting the standard for portable marquee fabrics.

The Limitations Of The Existing Fabrics

To date, there has been no “perfect” fabric in the marquee industry. There have basically been two options, a) a dyed polyester or b) a thick PVC tarpaulin. But neither of these fabrics have been exactly what our customers have demanded, so we set out to revolutionise the industry.

The Shortcomings Of Polyester

Stock dyed polyester has been a staple of the industry for decades. This is what most manufacturers use when they make their unprinted/plain marquee roofs. A great fabric from a usability perspective - nice and light and easy to use, but severely lacking in the longevity department and definitely a fabric with a limited lifespan and scope.

Low Outdoor Durability

Polyester is made up of long-chain plastic polymers. Through time, UV light will attack the bonds between these polymers and the material will lose it’s tensile strength. This will eventually result in the fabric tearing, typically along existing stress points (ie. seams).

The typical lifespan of a polyester roof is about 1000 hours (equivalent of two full day uses per week, for a year) of UV exposure before it loses so much strength that a moderate gust of wind can tear the roof. Of course, that 1000 hours depends on where you are in Australia as the UV index is on average higher in say, Cairns, as it is in Hobart.

Susceptibility To Fade

No one in the marquee industry, including us, has ever warranted against fade claiming it was expected “wear and tear” on the tops and didn’t detract from the function of the roof of keeping you a) shaded and b) dry.

Rather than accept the “status quo” of the industry, we’ve decided to raise the standard. At the end of the day, we believe a marquee is a representation of your business, and your brand. We just don’t think it’s good enough for a marquee to fade, even if it is still capable of performing its basic functions.

The Shortcomings Of PVC

PVC is a great durable fabric. It is colourfast, and has great long term durability outdoors for up to 5 years - so we like it. But there are few major reasons why we don’t love it.

Poor Usability

PVC is heavy and cumbersome to use. The fabric is heavy in weight, making it difficult to handle. It also has very little ductility making it further more difficult to a) fit to frames, but also b) to open the marquee. This kind of goes against the idea of a “portable marquee” when it’s difficult to use, hence we’ve generally only ever recommended PVC for semi permanent applications (i.e. carports).

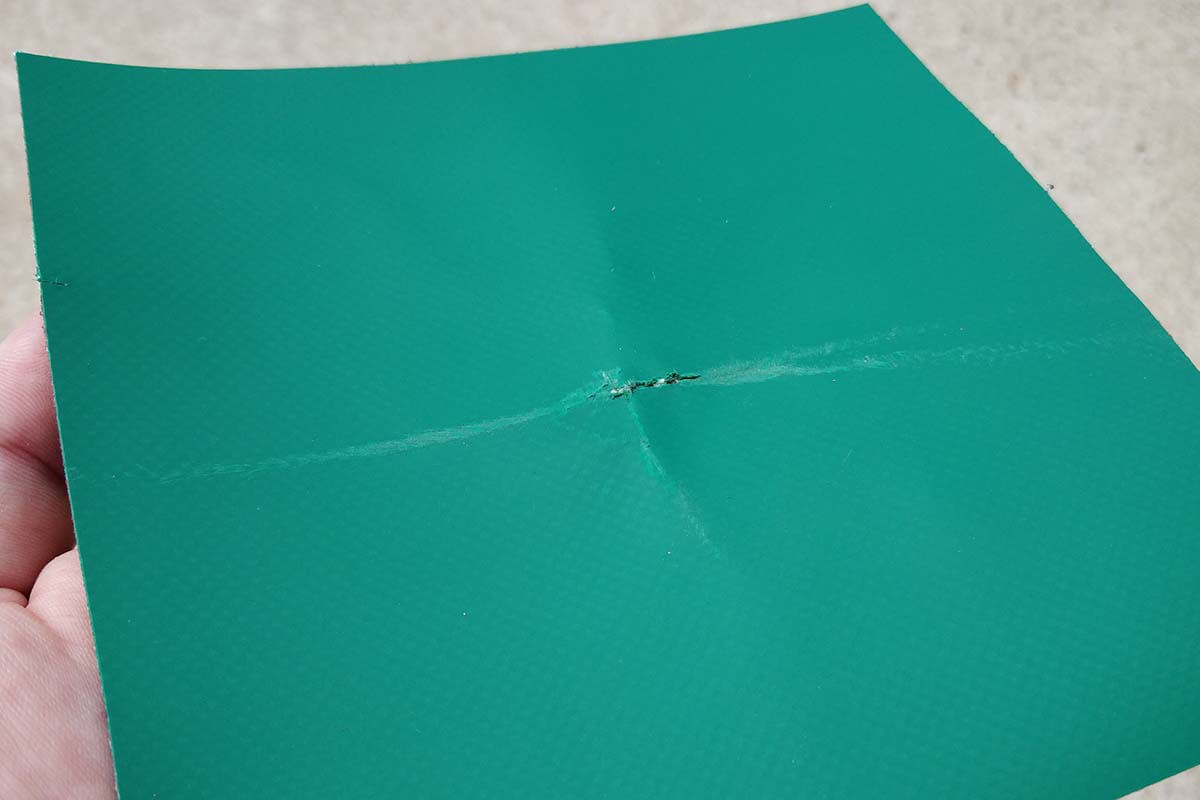

Minimal Abrasion Resistance

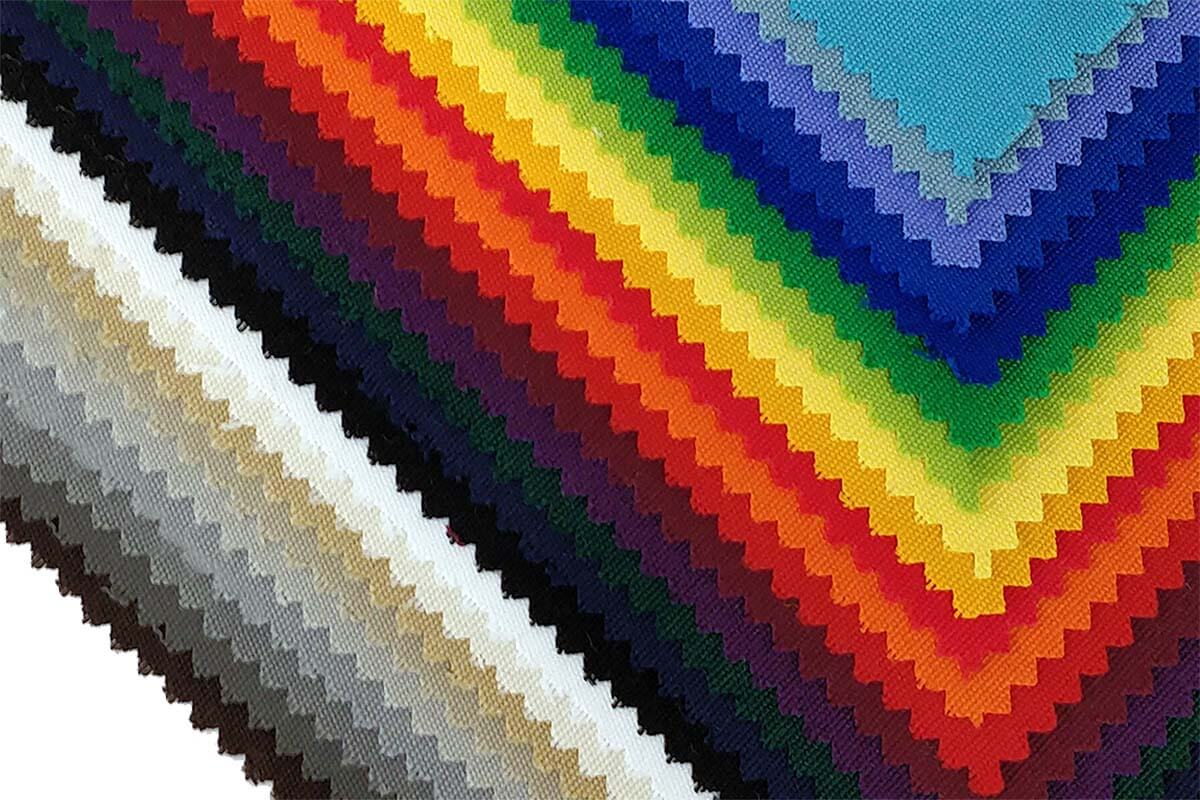

PVC tarpaulin is made up of an inner polyester mesh that is coated with PVC. The PVC itself is actually a relatively soft material, and because of its low ductility and heavy weight is susceptible to damage from abrasion over time.

When a point (formed when folded / creased) or hem rubs against concrete, it will wear down the outside PVC layer and expose the inner polyester mesh. Over time, this will damage the material.

Where NextUV Was Developed

We set out to develop a fabric that was a balance between PVC and polyester. The fabric should have the ease of use of polyester, but the outdoor durability of PVC. All meanwhile being reasonably priced.

During the development process for NextUV, we met Kerrie who is based in Mutitjulu (one of those places facing extreme sun and UV….every day) right next to Uluru. We thought that this location was the perfect setting to test our NextUV as it provides the most extreme conditions possible. If it can survive here, it can survive anywhere in Australia.

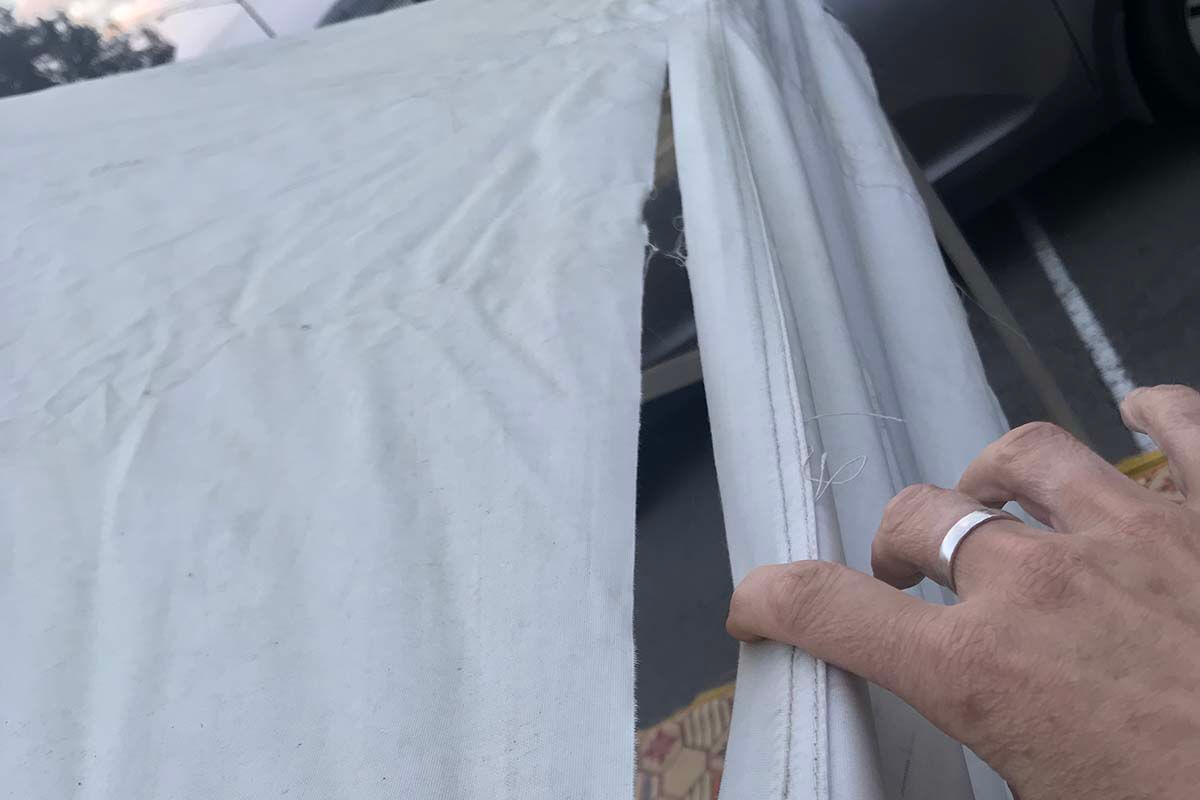

To prove the quality of NextUV, we wanted to have a fair comparison of long term sun exposure. So instead of supplying Kerrie with an industry standard polyester roof, we supplied her with a NextUV roof, with polyester sides as part of our research and development process.

We did this knowing that sidewalls are typically least affected from UV fade / wear, as they are mounted vertically and are often not operating in direct sunlight, meaning they receive less exposure to severe UV. Put simply, we tested worst case for NextUV vs best case scenario for polyester.

What Was The Feedback?

“Thought you may be interested in these. We had a storm so unfurled the side window which had been rolled up since just after the shade was erected. The colour difference was stark to say the least but the roof remains unchanged.” Kerrie Stevens - ARRCS Mutitjulu Aged Care

You can see here the NextUV roof still looks as black as the day it was set up. The polyester however has faded significantly, which is evident in comparison to the mostly black polyester window cover that has had minimal sun exposure.

Why NextUV Is The Perfect Marquee Fabric

NextUV is the perfect balance between a fabric that is easy to use yet has excellent outdoor durability properties. NextUV™ has been developed in response to years of customer feedback that polyester fabric roofs do not last long enough in commercial applications, and PVC is too heavy and impractical for regular use.

NextUV Features

✔ 5 year no significant fade guarantee

✔ 5 year no significant strength loss guarantee

✔ Abrasion & tear resistant

✔ 5000mm waterproof

✔ UPF50+ rating

✔ Anti-pilling & Anti-mildew

✔ Flame retardant

✔ Oil & water repellent

✔ Alkane, acid, and salt resistant

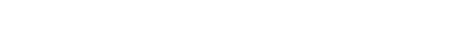

Colours

➤ 4 colours kept in stock

➤ 24 colours available made to order

➤ See all the NextUV™ colours

Testing Completed

ASTM D5034-09, UNE EN ISO 13934-1, ASTM D1424-09, UNE EN ISO 13937-3, AATCC118, AATCC22, AATCC147 2011&30:2004 / AATCC100 2012, EN ISO 12947-2:2016, ISO811, UNE EN ISO 12945-2, ISO 15025:2000, UNE EN 25077:1996, AATCC 16, ISO105B04, UNE-EN ISO 105-E03:1997

Conclusion & Summary

Polyester and PVC have long been the staples of the industry. Great in their time, but limited in their scopes; many customers have been left feeling dissatisfied and let down by an industry that has not listened to growing demand.

Several years ago, we set out to develop the perfect marquee fabric. A combination of all the best properties of polyester and PVC roofs, but with none of the drawbacks.

Extensive R&D and testing in one of the harshest Australian environments has led us to develop NextUV, which pushes all the boundaries of what someone should expect from a marquee fabric. Not only lightweight and easy to use, NextUV also carries a 5 year guarantee against no significant fading or structural degradation.

That’s what Technishelter is about: setting the standard.